What is a Pre-Engineered Steel Building Package?

Table of Contents

In the ever-evolving world of construction, innovation reigns supreme.

One of the radical innovations is the Pre-Engineered Steel Building.

However, you may be wondering, what exactly is a pre-engineered steel building? Basically, it’s a building that comes with a collection of pre-fabricated components.

Unlike traditional construction methods, the pre-engineered building components arrive at the site ready to be assembled like a Lego set, a giant steel Lego set.

While Northern Steel Buildings can supply the metal components and the insulation, as the client, you will need to consider site preparation, mechanical work, electrical design, as well as secure an engineered foundation.

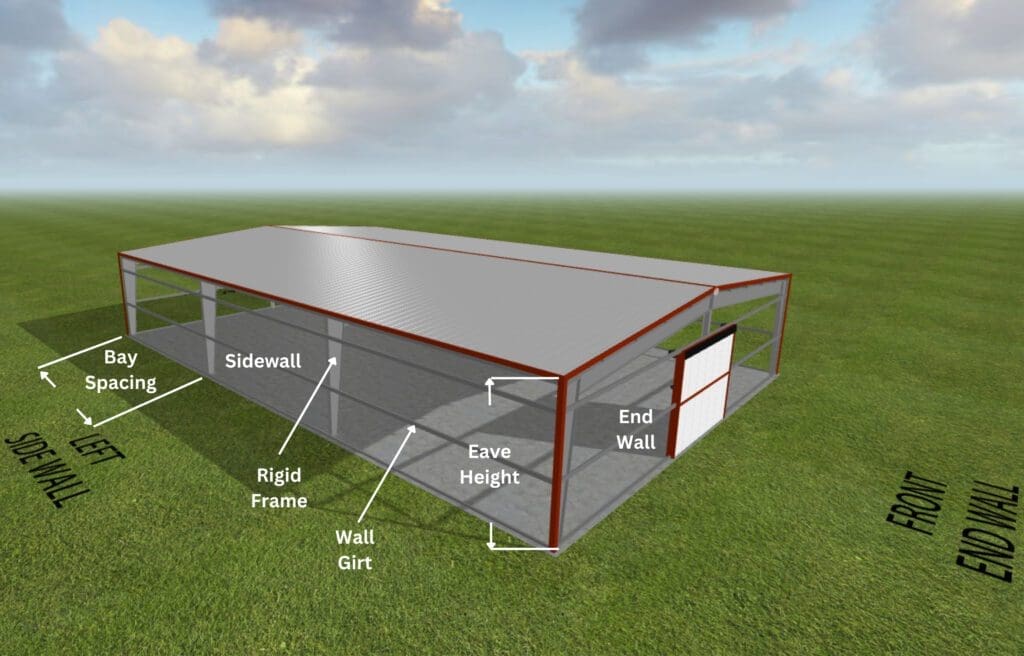

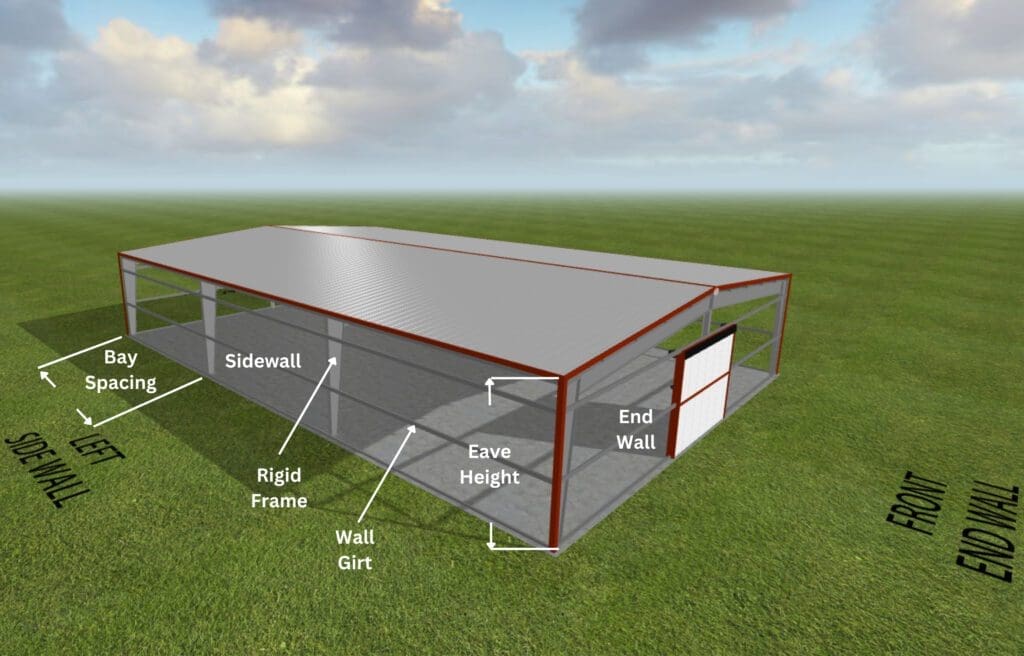

The Building Blocks of a Pre-Engineered Steel Building

A Pre-Engineered Steel Building consists of several key components, each playing a vital role in the overall structure. Let’s break down the major components:

Primary Components

Main Frame

The main frame forms the backbone of the pre-engineered steel building. It includes rigid steel frames comprising tapered columns and rafters. The flanges are connected to the webs through continuous fillet welds on one side, ensuring structural integrity and stability.

Columns

Columns are the vertical load bearers of the building, responsible for transferring the weight to the foundation. In pre-engineered steel buildings, columns are typically constructed using cost-effective I-sections. These columns gradually increase in width and breadth from bottom to top, optimizing load distribution.

Rafters

Rafters are sloped structural members that support the roof deck and its associated loads. They extend from the ridge or hip to the eave or wall-plate, ensuring the roof’s stability and structural integrity.

Secondary Components

Secondary structural members are crucial for providing support to the walls and roof panels. These include:

Purlins and Girts

Purlins are used on the roof, while girts are used on the walls. These cold-formed “Z” sections with stiffened flanges provide essential support to the building envelope.

Eave Struts: These unequal flange cold-formed “C” sections play a vital role in the intersection of the sidewall and the roof, enhancing structural stability.

Bracings

Bracings are essential for ensuring the building’s stability against longitudinal forces such as wind, cranes, and earthquakes. Diagonal bracing is commonly used in the roof and sidewalls, providing robust support.

Sheeting or Cladding

The sheets used in pre-engineered steel buildings are constructed from base materials like Galvalume-coated steel. These sheets, made from cold-rolled high tensile steel, offer exceptional strength and durability.

Accessories

Accessories are the non-structural components that complete a pre-engineered steel building. These include bolts, turbo ventilators, skylights, louvers, doors, windows, roof curbs, and fasteners. These accessories add functionality and aesthetics to the building, making it a fully operational and visually appealing structure.

In the realm of construction, pre-engineered steel buildings are reshaping the landscape. Their efficient design, lightweight nature, and cost-effectiveness make them a top choice for a wide range of applications, from industrial facilities to commercial spaces.

Ready to get started?

Give us a call at 1 (877) 751-3486 or try our new 3D Builder to get a quote on your project!