Steel Building Foundations

Selecting the right foundation is a big decision when planning a pre-engineered steel building.

There are several types of foundations to consider including slab, pier, and floating foundation. The type you choose will depend on the size and weight of the building, the soil conditions at the site, and the local building codes. It’s important to work with an experienced contractor who can help you evaluate your options.

Table of Contents

NOTE: Foundations for steel building kits must be engineered.

Key Takeaways

- Your steel building foundation should be done by a qualified engineer taking into account local building codes.

- Factors to consider include building size, building weight, and soil conditions.

- Working with an experienced contractor can help you evaluate your options and make an informed decision.

Types of Foundations for Pre-Engineered Steel Buildings

Here are three common types of foundations for pre-engineered steel buildings:

Slab Foundation

A slab on grade foundation is the most common type of steel building foundation. Like its name suggests, it involves pouring a concrete slab directly onto a levelled surface, usually a sand bed to provide a cushion and effective drainage system. This type of foundation works well for buildings that don’t require a basement and is cost-effective and easy to construct.

Pier and Beam Foundation

A pier and beam foundation involves using concrete piers or columns to support the steel structure. The piers are placed deep into the ground to provide added support. This type of foundation is suitable for buildings that require a raised floor or a basement. Pier and beam foundations are more expensive than slab foundations but offer more stability and durability.

Floating Foundation

A floating foundation is often used for buildings located in areas with high water tables or unstable soil. It involves using a concrete slab that is supported by a system of steel columns or piers designed to “float” on top of the soil, which helps to distribute the weight of the building evenly. This type of foundation is more expensive than slab-on-grade foundations but offers even more stability and durability.

Factors Influencing Foundation Choice

When it comes to choosing the right steel building foundation, there are several factors that you need to consider.

Soil Characteristics

The type of soil plays a significant role in foundation selection. Some soils are softer and less dense than others, which can affect the stability and longevity of your building. It’s essential to have a soil test done to determine the soil characteristics of your building site.

Building Load Requirements

Obviously, the steel building foundation needs to be strong enough to support the weight of your building and any type of equipment or vehicles that are stored inside. Therefore, you need to consider the size and weight of your building, as well as the load requirements of your equipment and machinery.

Local Climate and Weather Patterns

Obviously, you’ll need to choose a foundation that can withstand your local weather conditions, whether that’s high winds, heavy rain, or snow. Similarly, if you live in an area that experiences earthquakes, you need to choose a foundation that is designed to withstand seismic activity.

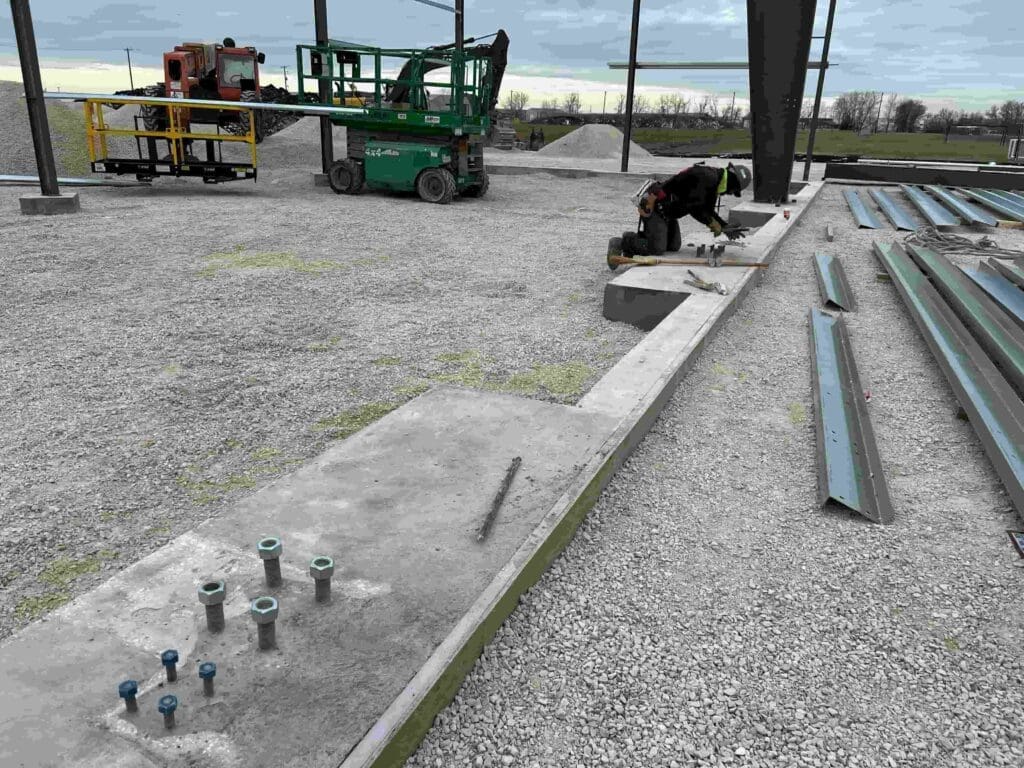

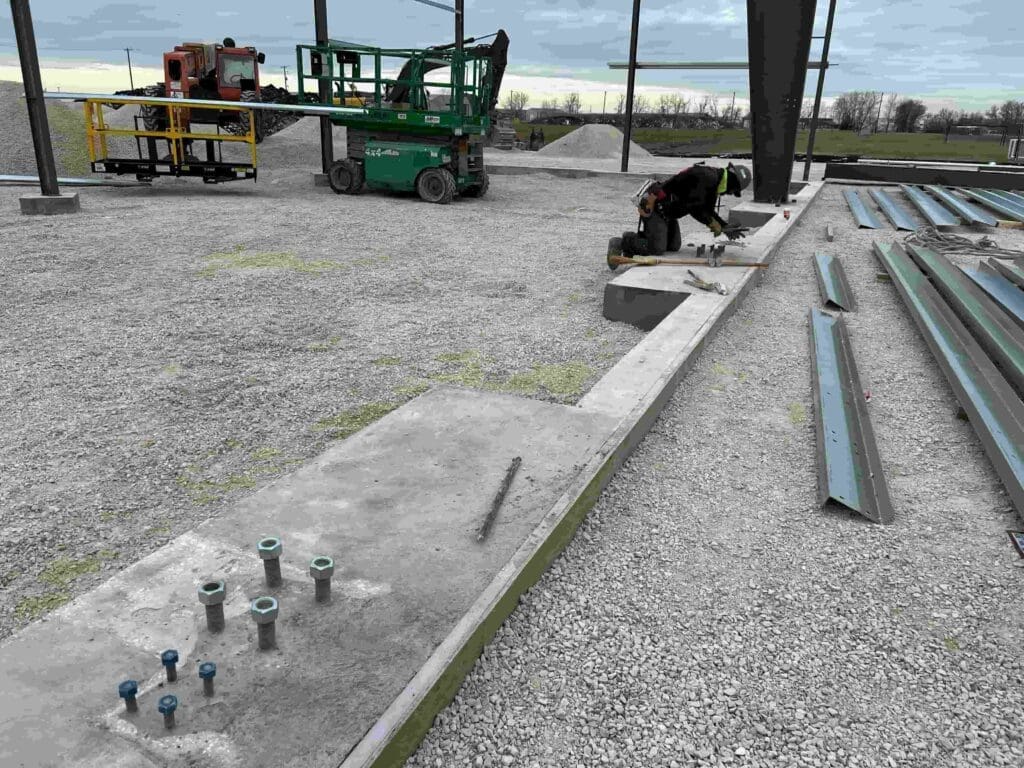

Foundation Construction Process

Constructing a steel building foundation begins with site preparation, formwork and reinforcement, and concrete pouring and curing.

Site Preparation

Site prep includes clearing the area of any debris or vegetation and levelling the ground. You also need to ensure that the site is properly drained to prevent water from accumulating around the steel building foundation. This can be accomplished by grading the site or installing a drainage system.

Formwork and Reinforcement

Once the site is prepared, you can begin constructing the formwork for the steel building foundation. Formwork is the temporary structure used to create the shape of the foundation. It is typically made from wood, metal, or plastic and is designed to hold the concrete in place until it has cured.

Reinforcement is also added to the foundation during this stage. Reinforcement is typically made from steel bars or wire mesh and is used to add strength and stability to the foundation. The reinforcement is placed inside the formwork before the concrete is poured.

Concrete Pouring and Curing

The final step in the steel building foundation construction process is pouring the concrete and allowing it to cure. The concrete is typically poured in one continuous pour to ensure that it is structurally sound. Once the concrete is poured, it needs to be allowed to cure for several days.

Anchor Bolts

Typically made of high-strength steel, anchor bolts are embedded into the concrete foundation during its construction. They play a crucial role in securing pre-engineered steel buildings to their foundation.

Securing the Structure

Anchor bolts provide a means of attaching the steel building foundation’s columns or base plates to the foundation. Once the concrete foundation has cured, the steel columns or base plates are positioned over the embedded anchor bolts, and nuts and washers are tightened onto the bolts to securely fasten the building to the foundation. This anchoring mechanism ensures that the building remains firmly in place, especially during high winds, seismic events, or other external forces.

Resisting Uplift Forces

In addition to securing the building to the steel building foundation, anchor bolts help resist uplift forces that may occur during extreme weather events such as hurricanes or tornadoes. These forces exert an upward pressure on the building, trying to lift it off the foundation. By anchoring the building securely to the foundation, anchor bolts help counteract these uplift forces and prevent structural damage or failure.

Maintaining Alignment and Stability

Properly installed anchor bolts help maintain the alignment and stability of the steel structure. They ensure that the columns are correctly positioned relative to the foundation, preventing shifting or movement that could compromise the integrity of the building. This is particularly important for multi-story buildings or structures subjected to dynamic loads.

Meeting Building Codes and Standards

Anchor bolts are often required by building codes and engineering standards to ensure the structural stability and safety of pre-engineered steel buildings. The size, spacing, and depth of anchor bolts are specified based on factors such as building size, wind loads, seismic activity, and soil conditions. Compliance with these requirements helps ensure that the building meets or exceeds safety standards and regulatory requirements.

Are You Looking To Build?

Give us a call today at 1 (877) 751-3486 or try our new 3D BUILDER

Visualize your project with our easy-to-use 3D Design Tool. Whether it’s a small shop, a classic 40×60 steel building, or a large manufacturing plant, just input your building dimensions and explore what your project could look like with a variety of door options, a mezzanine, or skylights. When you’re finished, submit your design for your custom steel building info and pricing.

Looking for a quote?

Our building consultants are here to help you find the steel building foundation that works best for you. Contact us today to learn more and take the first step towards realizing your steel building dreams.

Give us a call at 1-877-751-3486.

Or request a free quote.

FAQ

What are your lead times?

For current lead times, reach out to our building team at 1-877-751-3486

Can I assemble and install myself?

Yes! If you have the right tools and experience, you can save on installation costs. However, partnering with an experienced installation crew can save you time and money.

Can I install a crane in my steel building?

Yes! You will want a qualified engineer or crane specialist to ensure the building is designed to accommodate the crane’s weight and movement.

Can I easily add expand my steel building in the future?

Yes! Thanks to their standardized componenets, pre-engineered steel buildings allow for easy expansion as your needs change.

How long does construction take?

The time to erect a pre-engineered steel building depends on the size and scope, as well as the weather. However, many small to medium sized buildings can take around 4-6 weeks.

What kind of permits do I need before building?

Building codes vary between jurisdictions to ensure structures can weather whatever the local climate can throw at it. Below are some common questions you should ask your local building authority:

-What is the property zoning?

-What are the property setbacks?

-What is the live load or ground snow load?

-What is the wind load?

-What is the seismic code?

-Are structural calculations required?

-What kind of permits or fees are required?

Who is Northern Steel Buildings?

Northern Steel Buildings was founded with over 50 years of combined steel experience. We supply custom steel buildings to owners across Canada and the United States. We can also refer you to local experienced installers if you choose not to DIY. Contact our helpful building team for a free quote or if you have any questions about steel buildings!

How do I get a quote on a steel building?

Give our friendly building team a call! Helping folks plan out their custom steel building is our passion.