Table of Contents

1. Wood is cheap, what are the advantages of pre engineered steel buildings?

Like all things, you get what you pay for. That is especially true when it comes to pre engineered steel structures.

While the upfront costs are higher, the benefits of steel are many, and may actually save you more money in the long run.

Here are 4 reasons why you’ll regret NOT embarking on a pre engineered steel building construction:

- Longevity: Pre engineered steel buildings not only last much longer but also require less maintenance.

- Quick Construction: Pre engineered steel buildings have quick assembly times thanks to the bolt-together, pre-cut components and pre-punched holes.

- Durability: Pre engineered steel buildings are much more durable, able to withstand weather events like snowstorms, high winds, and earthquakes. And unlike wood, steel is non-combustible.

- More Space: Pre engineered steel buildings don’t need interior columns which means total flexibility for how you use the space, whether it’s storing large farm implements or installing a crane for your factory. Either way it’s more usable square footage.

2. What gauge of steel should I use?

Steel gauges are used to measure the thickness of steel sheets. The gauge of a steel sheet is determined by measuring its thickness in fractions of an inch. A higher gauge number indicates a thinner steel sheet, while a lower gauge number indicates a thicker steel sheet. (For example, a 26-gauge steel sheet is actually thinner than a 24-gauge steel sheet.)

The industry standard is 26 gauge steel for most commercial and residential buildings, though the thicker 24 gauge steel is sometimes used for standing seam panels and buildings that need to withstand high wind or snow loads.

Pre engineered steel buildings with a steep roof or vertical walls may also require a thicker steel like the 24 gauge.

In the end, your choice of steel gauge depends on the size and type of building, the weight it will support, as well as local building codes and regulations.

3. What type of finish should I choose? Galvalume? Ceram-a-Star? Trinar?

There are a few options when it comes to your steel finish in the design of pre engineered steel buildings. Galvalume, Ceram-a-Star and Trinar all provide a similar level of rust and corrosion resistance but there are some slight differences between them.

Galvalume is an industry standard known for its bright, shiny finish. It’s made up of mostly aluminum and zinc, and a small amount of silicone.

Ceram-a-Star is a silicone-modified polyester coating system that provides excellent color retention and resistance to chalking and fading. This coating creates a durable finish that is resistant to weathering and corrosion.

Trinar is a high-performance coating made up of a fluoropolymer resin and ceramic pigmentation that provides protection against weather, chalking, and fading. It features a high gloss finish and is often used in areas with harsh climates.

Steel Finish Warranty

Galvalume comes with a 25 year warranty while the painted coating with Ceram-A-Star comes with a 40 year warranty. Painted coating with Trinar comes with a 35 year warranty.

4. What type of roof do I need? Screw down? Standing seam?

A screw-down roof (SDR) consists of metal panels secured using screws and washers. A screw-down roof is a popular choice for low-slope roofs on pre engineered steel buildings because they provide excellent weather resistance and are typically less expensive and easier to install than a standing seam roof. However, the screw-down roof doesn’t allow for thermal expansion and so the regular expansion and contraction of the steel will cause wear and tear over time.

A standing seam roof (SSR) is a common feature for commercial and industrial buildings as they provide a refined look, are extremely durable, and provide excellent weather resistance. The best part is, thanks to their interlocking metal panels joined together with concealed fasteners, they allow the roof to expand and contract while the clips remain fastened and the panels can move back and forth.

Want lower maintenance? Definitely consider a standing seam roof.

Not afraid of replacing screws in 10-15 years and looking to save on building costs? The screw-down roof might be your ideal option.

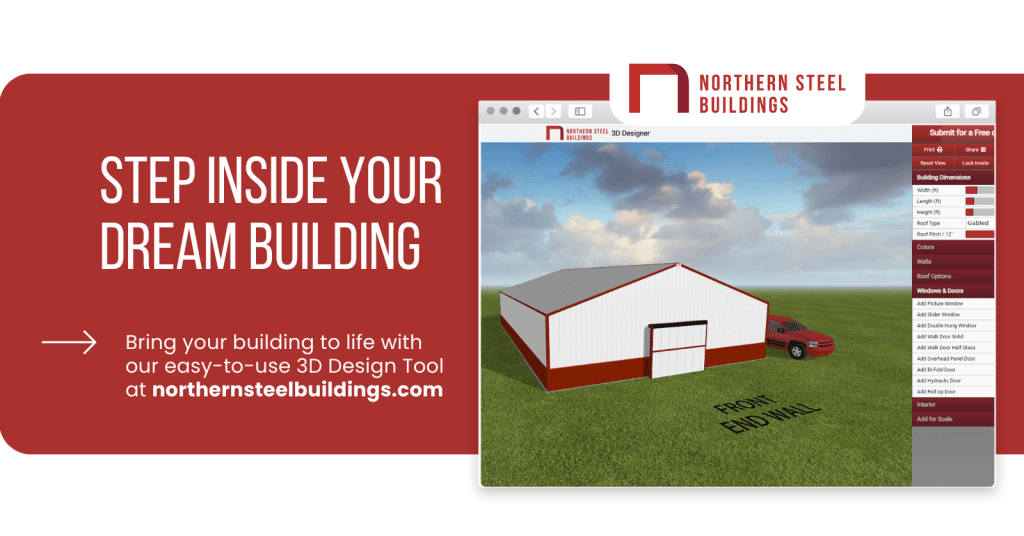

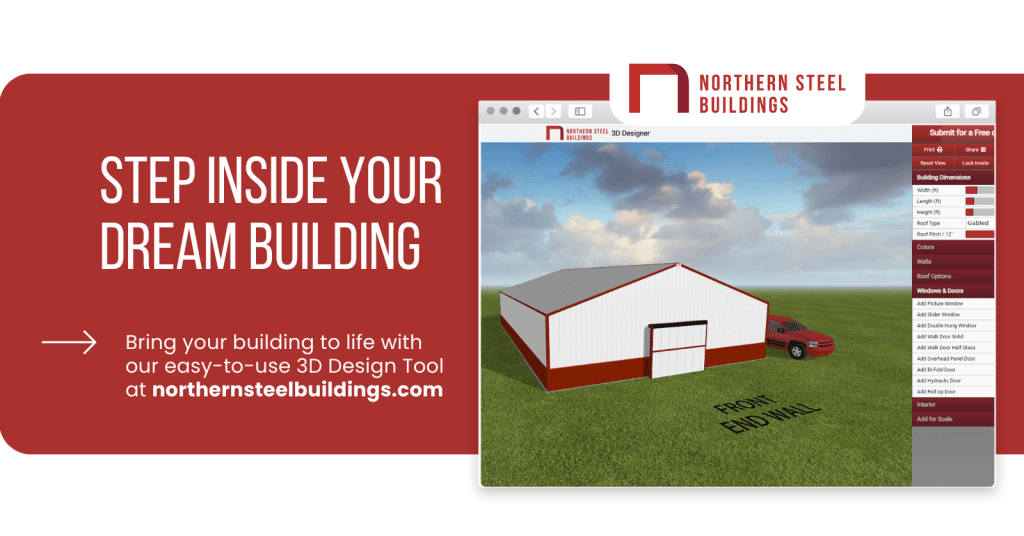

Want to see YOUR building?

Are you planning a new build? Want to see what your pre engineered steel building would look like? Visualize your project with our easy-to-use 3D Design Tool. Just input your building dimensions and explore what a pre engineered building could look like with a variety of door options, a mezzanine, or skylights.

5. What kind of foundation do I need for a steel building?

The foundation design for a pre engineered steel building should be done by a qualified engineer, taking into account the specific needs of the building and the local building codes and regulations.

Foundation types include:

Concrete slab foundation: A common choice for smaller steel buildings, the concrete slab is poured directly onto a prepared base and serves as the floor of the building.

Pier foundation: Concrete footings and columns support the building. This type of foundation is often used for larger steel buildings or in areas with unstable soil conditions.

Strip foundation: A continuous concrete strip supports the weight of the building. This type of foundation is used when the load on the building is evenly distributed.

Trench foundation: Similar to a strip foundation, but is deeper and narrower. This type of foundation is used when the soil is unstable or the load on the building is not evenly distributed.

Speak with an expert!

Share the vision for YOUR building with a helpful building consultant at Norther Steel Buildings. Steel buildings are what we do! Give us a call at 1 (877) 751-3486.