Building a Steel Structure: Your 7-Step Checklist

Intro

Building a steel structure is no small feat.

It requires careful planning, precise execution, and expert knowledge of the materials and processes involved. From the initial design phase to the final delivery, every step in the process is critical to ensuring the structure is safe, durable, and meets the needs of the client.

In this article, we’ll take a broad look at the process of building a steel structure, from the initial design and engineering to the fabrication and delivery of the final product. By the end, you’ll have a good understanding of the journey ahead of you.

Designing a steel structure

The first step in building a steel structure is design.

This often means working with an architect or engineer to create a blueprint that outlines the structure’s dimensions, materials, and other key details. The design phase is critical in ensuring the building will meet the needs of the client, is structurally sound, and complies with all local building codes and regulations.

Once the design is complete, it must be reviewed and approved by the local authorities. This involves obtaining necessary permits and approvals, which can be a lengthy process.

Obtaining necessary permits and approvals

Before construction can begin, you’ll need to submit the design plans to the relevant departments for review and approval. The process can be time-consuming, and builders must ensure that they have all the necessary paperwork in order before beginning construction. This includes meeting fire safety standards, ensuring that the structure is accessible to people with disabilities, and complying with zoning regulations.

Preparing the site for construction

Once all the necessary permits and approvals have been obtained, builders can begin preparing the site for construction; clearing the land, leveling the ground, and creating a foundation for the structure. It goes without saying that the site must be properly prepared before beginning construction to ensure that the structure is safe and stable.

Setting the foundation of the steel structure

The foundation is one of the most critical parts of the steel structure. It must be strong enough to support the weight of the structure and resist the forces of wind, rain, and other weather conditions. The foundation design for a pre-engineered steel building should be done by a qualified engineer, taking into account the specific needs of the building and the local building codes and regulations. There are several types of foundations that can be used for steel structures, including:

Slab-on-grade: This is a simple foundation that involves pouring a concrete slab directly on the ground. It is commonly used for smaller structures and in areas with stable soil conditions.

Pier and beam: This involves creating a series of piers to support the weight of the structure. Beams are then placed on top of the piers to support the structure’s weight.

Deep foundation: This involves creating a foundation that extends deep into the ground. It is commonly used in areas with unstable soil conditions or where the structure is particularly heavy.

Assembly and Installation

Once the foundation is in place, builders can begin erecting the steel structure. This involves assembling the steel frame, which is typically done using cranes and other heavy equipment. Builders must ensure that the steel frame is erected correctly to ensure that the structure is safe and stable.

Once the steel frame is in place, builders can begin installing insulation, roofing, and siding. This involves adding layers of insulation to the walls and roof to ensure that the structure is energy-efficient and comfortable. Builders must also install roofing and siding materials that are durable and can withstand harsh weather conditions.

Finishing touches and final inspections

Once all the major construction is complete, builders can begin adding finishing touches to the structure. This may include installing doors and windows, painting the walls, and adding landscaping around the structure. Builders must also conduct final inspections to ensure that the structure meets all local building codes and regulations.

Maintenance and upkeep of a steel structure

Steel structures are designed to be durable and long-lasting, but they still require regular maintenance and upkeep to ensure that they remain safe and functional. This may include regular inspections, cleaning, and repairs as needed. Builders must ensure that they have a plan in place for maintaining the structure after it is completed.

Conclusion

Building a steel structure requires careful planning, precise execution, and expert knowledge of the materials and processes involved. From the initial design phase to the final delivery, every step in the process is critical to ensuring the structure is safe, durable, and meets the needs of the client. Builders must keep in mind the unique challenges posed by local weather conditions and seismic activity, and ensure that the structure is designed and constructed to withstand these challenges. By following the steps outlined in this article, builders can create a safe and sturdy steel structure that will stand the test of time.

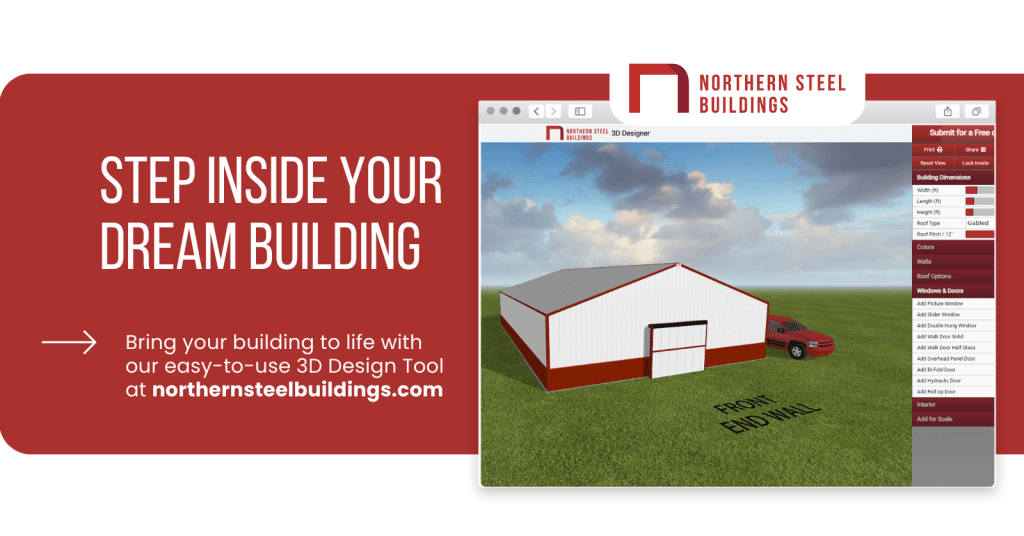

Want to see your building now?

Visualize your project with our easy-to-use 3D Design Tool. Whether it’s a small shop, a classic 40×60 steel building, or a large manufacturing plant, just input your building dimensions and explore what your project could look like with a variety of door options, a mezzanine, or skylights. When you’re finished, submit your design for your custom steel building info and pricing.